Inside the Innovation Engine: How Artisan Labs' R&D Team is Revolutionizing Contract Manufacturing

Share

From Startup to Industry Leader: 100+ Active Projects Demonstrate Rapid Market Adoption

HANSEN, IDAHO — Just months after opening its doors in October 2021, Artisan Labs has rapidly emerged as a driving force in cosmetic contract manufacturing, with its research and development team now managing over 100 active projects for 25 international beauty brands.

This remarkable growth trajectory showcases how next-generation contract manufacturers can quickly establish market leadership through innovative R&D capabilities and client-centric approaches that traditional manufacturers struggle to match.

The Science Behind the Success: Inside Artisan Labs' R&D Innovation Center

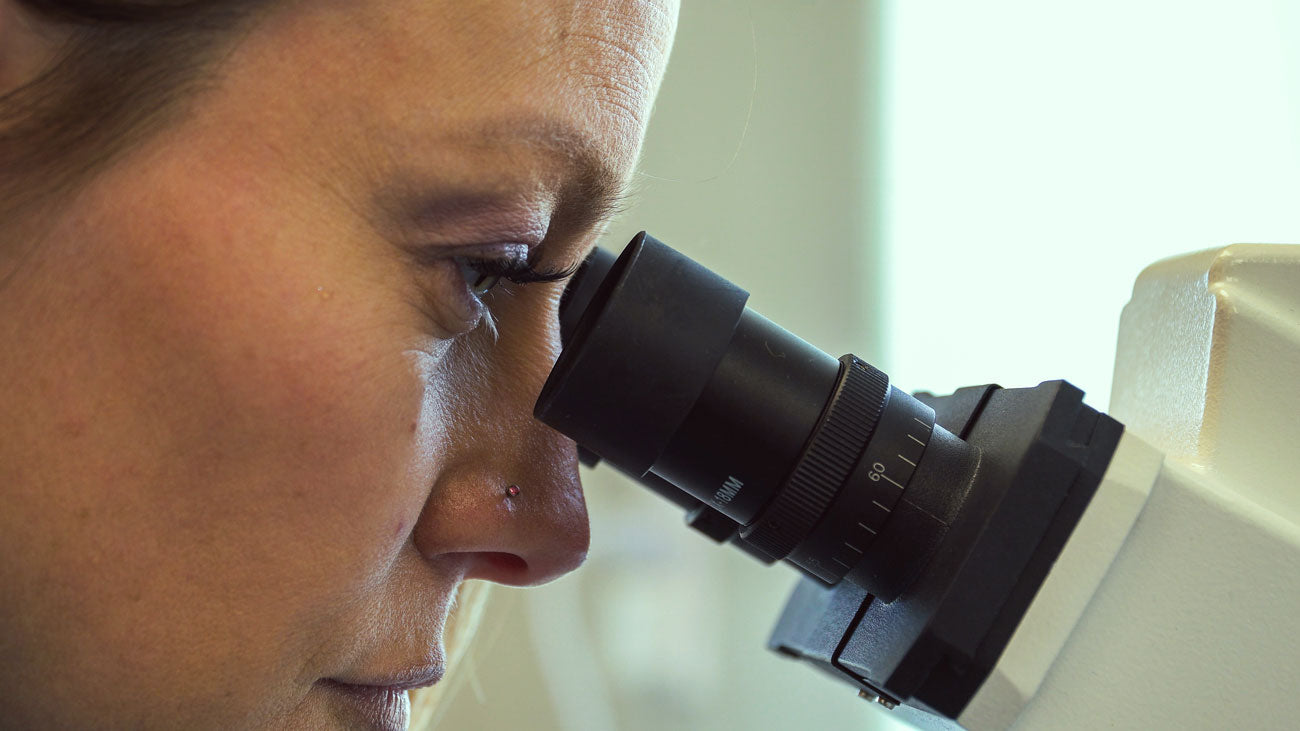

At the heart of Artisan Labs' rapid expansion lies a state-of-the-art research and development facility where scientific innovation meets commercial viability. Led by Research and Development Manager Mara Reed and supported by specialized technicians like Bailey Stonebraker, the R&D team represents the new frontier of cosmetic formulation excellence.

Advanced Formulation Capabilities

The Artisan Labs R&D department operates as a comprehensive innovation center, equipped with sophisticated ingredients libraries and cutting-edge formulation technologies that enable rapid product development for diverse beauty brands.

Ingredient Innovation: The facility houses an extensive collection of specialized ingredients, allowing formulators to create unique combinations that differentiate client products in competitive markets.

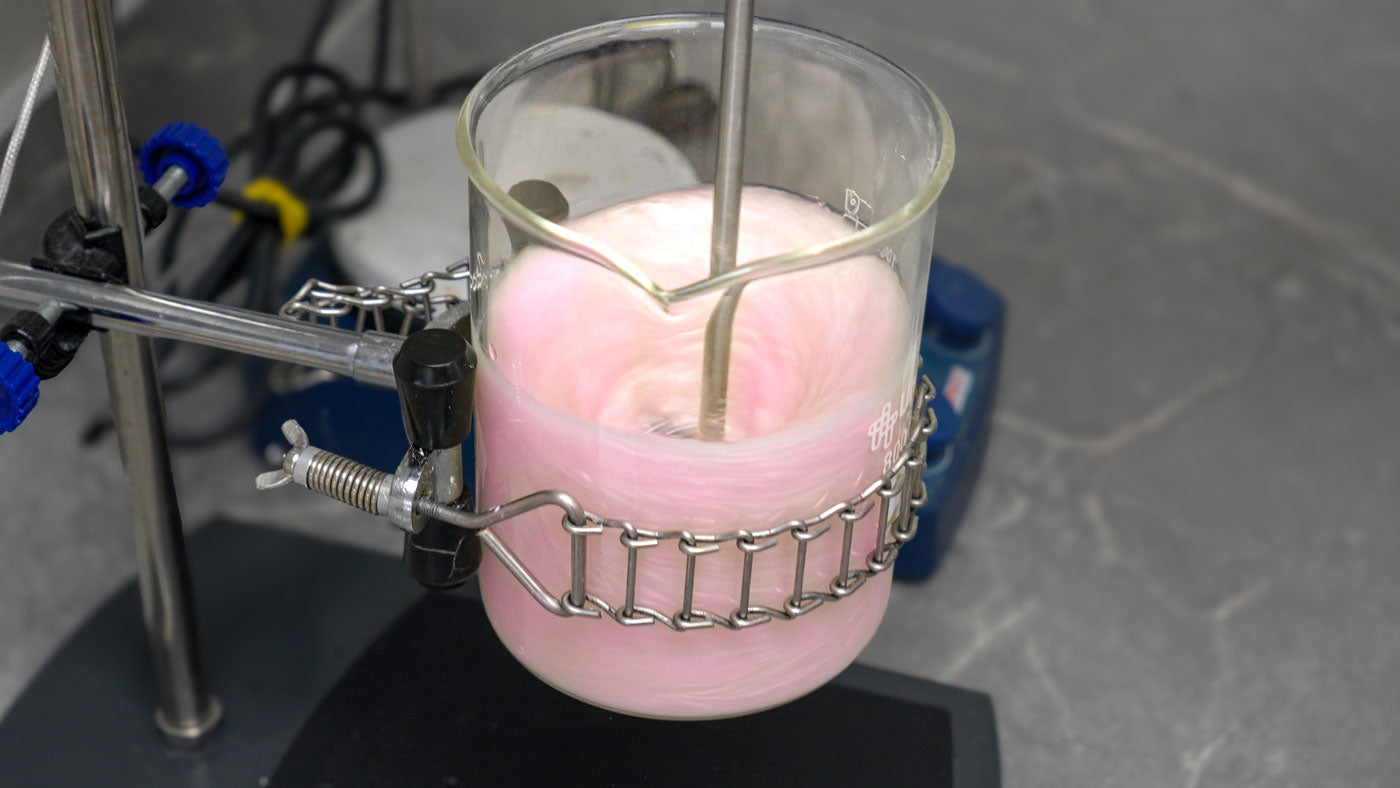

Process Optimization: Advanced mixing and measuring capabilities ensure consistent, scalable formulations that maintain quality from laboratory development through full-scale production.

Rapid Prototyping: The team's ability to quickly iterate on formulations accelerates time-to-market for beauty brands, providing crucial competitive advantages in the fast-paced cosmetics industry.

Breaking Down the Numbers: From Zero to 100+ Projects

The transformation from a startup contract manufacturer to managing over 100 active projects in just months represents one of the most impressive growth stories in the Idaho manufacturing sector.

Project Portfolio Analysis

25 International Beauty Brands: Artisan Labs has successfully attracted clients from diverse markets, demonstrating the global appeal of their R&D capabilities and manufacturing quality.

100+ Active Projects: This project volume indicates sophisticated project management systems and scalable R&D processes that can handle multiple complex formulation challenges simultaneously.

Rapid Market Penetration: The speed of client acquisition suggests strong industry relationships and proven capabilities that established brands trust with their most important product developments.

What Drives Client Adoption

Several factors explain why beauty brands are rapidly choosing Artisan Labs for their most critical product development needs:

Scientific Expertise: The R&D team brings deep knowledge of cosmetic chemistry, ingredient interactions, and formulation optimization techniques.

Flexible Collaboration: Unlike larger manufacturers with rigid processes, Artisan Labs adapts to each client's unique requirements and development timelines.

Innovation Focus: The team prioritizes creative problem-solving and cutting-edge formulation approaches that help brands differentiate their products.

Quality Assurance: Rigorous testing and quality control processes ensure that every formulation meets the highest standards for safety and performance.

The Research and Development Advantage in Contract Manufacturing

Modern contract manufacturing success depends on R&D capabilities that extend far beyond basic production services. Artisan Labs has positioned itself at the forefront of this evolution by investing heavily in scientific talent and advanced development processes.

Comprehensive Development Services

The Artisan Labs R&D approach encompasses every stage of product development:

Concept Development: Working with brands to translate market insights and consumer needs into viable product concepts.

Ingredient Selection: Leveraging extensive ingredient libraries and supplier relationships to optimize formulation performance and cost-effectiveness.

Formulation Optimization: Iterative development processes that refine texture, performance, stability, and sensory characteristics.

Scalability Testing: Ensuring that laboratory formulations translate successfully to full-scale manufacturing processes.

Regulatory Compliance: Building regulatory requirements into the development process to streamline approval and market entry.

Behind the Scenes: The Daily Innovation Process

The R&D team's daily operations reveal the sophisticated processes that enable Artisan Labs to manage such an extensive project portfolio while maintaining high quality standards.

Advanced Project Management

Mara Reed, Research and Development Manager, oversees a complex portfolio of projects that require careful coordination and resource allocation:

Parallel Development: Multiple projects progress simultaneously, requiring sophisticated scheduling and resource management.

Client Collaboration: Regular communication with brand teams ensures that development aligns with market strategies and brand positioning.

Quality Protocols: Systematic testing and documentation processes ensure consistency and regulatory compliance across all projects.

Future Planning: Continuous evaluation of expansion needs and capability development to support growing client demands.

Technical Innovation at Work

Bailey Stonebraker, Research and Development Technician, represents the hands-on scientific expertise that drives daily innovation:

Precision Formulation: Careful measurement and mixing processes that ensure reproducible results and scalable formulations.

Testing Protocols: Comprehensive evaluation of formulation performance, stability, and safety characteristics.

Documentation Excellence: Detailed record-keeping that supports regulatory compliance and manufacturing consistency.

Continuous Learning: Staying current with industry trends and new ingredient technologies to enhance formulation capabilities.

Market Positioning: Why Brands Choose Emerging Manufacturers

The rapid adoption of Artisan Labs' services reflects broader industry trends toward working with innovative, agile contract manufacturers rather than traditional large-scale production facilities.

Competitive Advantages of Emerging Manufacturers

Flexibility and Responsiveness: Newer companies can adapt quickly to client needs and market changes without bureaucratic constraints.

Innovation Focus: Emerging manufacturers often invest more heavily in cutting-edge capabilities and technologies.

Personal Attention: Smaller client portfolios enable more dedicated attention and customized service approaches.

Cost Efficiency: Streamlined operations and lower overhead costs provide competitive pricing advantages.

Growth Partnership: Brands can grow alongside their manufacturing partners, developing long-term strategic relationships.

The Expansion Imperative: Planning for Future Growth

The rapid accumulation of projects and clients has prompted Artisan Labs to actively plan for expansion, ensuring that growth doesn't compromise quality or service levels.

Strategic Growth Planning

Facility Expansion: Additional laboratory and production space to accommodate increasing project volumes and client demands.

Team Development: Recruiting additional R&D professionals and technicians to maintain service quality while scaling operations.

Technology Investment: Continuous upgrading of equipment and capabilities to stay ahead of industry requirements and client expectations.

Process Optimization: Refining project management and development processes to maximize efficiency and maintain rapid turnaround times.

Capacity Building for Scale

The challenge of managing 100+ active projects requires sophisticated systems and processes that many traditional manufacturers lack:

Project Tracking Systems: Advanced software and documentation processes that enable real-time project monitoring and client communication.

Resource Allocation: Strategic planning that ensures adequate staffing and equipment availability for all active projects.

Quality Management: Scalable quality control processes that maintain standards regardless of project volume.

Client Communication: Systematic approaches to keeping all clients informed about project progress and timeline updates.

Innovation Trends Driving R&D Success

Artisan Labs' R&D capabilities align with key industry trends that are reshaping the cosmetic contract manufacturing landscape.

Emerging Market Demands

Clean Beauty Formulations: Increasing demand for natural, sustainable ingredients and environmentally conscious formulation approaches.

Customization and Personalization: Growing interest in tailored products that address specific consumer segments and individual needs.

Rapid Product Cycles: Shortened development timelines that require agile R&D processes and efficient project management.

Regulatory Complexity: Evolving safety and regulatory requirements that demand sophisticated compliance expertise.

Global Market Access: International expansion strategies that require understanding of diverse regulatory and market requirements.

Technology Integration

Advanced Testing Equipment: Investment in sophisticated analytical instruments that accelerate development and ensure quality.

Digital Collaboration Tools: Technology platforms that enable seamless communication with international clients and remote project management.

Data Management Systems: Comprehensive databases that track ingredient performance, formulation history, and regulatory information.

Automation Capabilities: Streamlined processes that reduce development time while maintaining precision and consistency.

The Economic Impact of R&D Excellence

The success of Artisan Labs' R&D operations extends beyond individual client relationships to create broader economic benefits for the region and industry.

Local Economic Development

High-Wage Scientific Jobs: R&D positions provide career opportunities for chemists, microbiologists, and technical specialists in rural Idaho.

Skills Development: Training and experience opportunities that build specialized capabilities in the local workforce.

Supplier Relationships: Connections with ingredient suppliers and equipment manufacturers that benefit the broader regional economy.

Innovation Culture: Establishing Idaho as a location where cutting-edge scientific work happens, attracting additional investment and talent.

Industry Leadership Position

Setting New Standards: Artisan Labs' rapid growth demonstrates what's possible when contract manufacturers prioritize innovation and client service.

Market Influence: Success stories influence industry trends and encourage other manufacturers to invest in R&D capabilities.

Talent Attraction: High-profile projects and rapid growth help attract top scientific talent to Idaho's emerging beauty manufacturing sector.

Looking Forward: The Future of Contract Manufacturing R&D

Artisan Labs' early success provides insights into how the contract manufacturing industry is evolving and what capabilities will define future leaders.

Industry Evolution Trends

Science-Driven Differentiation: R&D capabilities increasingly determine competitive advantage rather than just production efficiency.

Client Partnership Models: Deeper collaboration between manufacturers and brands in product development and market strategy.

Regulatory Expertise: Growing importance of compliance knowledge and regulatory navigation skills.

Sustainability Integration: Environmental considerations becoming central to formulation development and ingredient selection.

Global Market Sophistication: International clients demanding world-class capabilities regardless of facility location.

Artisan Labs' Strategic Position

The company's rapid project accumulation and client growth position it well for continued expansion and industry leadership:

Proven Capabilities: Track record with 25 brands and 100+ projects demonstrates operational competence and market appeal.

Scalable Systems: Investment in processes and technology that support continued growth without compromising quality.

Market Timing: Entry during a period of industry shortage and growing demand for innovative contract manufacturing services.

Strategic Location: Idaho's business advantages combined with access to skilled technical workforce.

Leadership Experience: Management team with proven industry expertise and successful track record.

Conclusion: Where Innovation Meets Opportunity

The story unfolding at Artisan Labs' Hansen facility represents more than just rapid business growth—it demonstrates how next-generation contract manufacturers can quickly establish market leadership through scientific excellence and client-focused innovation.

From opening in October 2021 to managing over 100 active projects for 25 international brands, Artisan Labs has compressed years of typical growth into months, creating a new model for how emerging manufacturers can compete with established industry players.

The R&D team's daily work—from Mara Reed's strategic project management to Bailey Stonebraker's precision formulation work—exemplifies the scientific rigor and innovation focus that modern beauty brands demand from their manufacturing partners.

As the company continues to expand its capabilities and client portfolio, Artisan Labs is not just participating in the beauty industry's evolution—it's helping to define what the future of contract manufacturing excellence looks like.

For beauty brands seeking innovative, responsive contract manufacturing partners, the Artisan Labs story demonstrates that remarkable capabilities and rapid growth can emerge from unexpected locations when scientific expertise meets market opportunity.

The next chapter of this innovation story is still being written, but the foundation of scientific excellence, client focus, and rapid execution suggests that Artisan Labs' impact on the contract manufacturing industry is just beginning.

Ready to experience the innovation advantage that's driving rapid growth for 25 international beauty brands? Contact Artisan Labs' R&D team to discover how our scientific expertise can accelerate your next product development project.

About the Innovation: This rapid growth from startup to managing 100+ active projects represents one of the fastest expansions in Idaho's manufacturing sector and demonstrates the market demand for innovative contract manufacturing approaches. For more information about Artisan Labs' R&D capabilities, visit our facility at 290 Highway 30 in Hansen, Idaho.