EXCLUSIVE: Inside Artisan Labs' Manufacturing Revolution - Where Precision Meets Innovation

Share

Behind-the-Scenes Look at How Next-Generation Contract Manufacturing is Transforming Beauty Production

HANSEN, IDAHO — In an exclusive behind-the-scenes look at one of Idaho's most rapidly growing manufacturing facilities, Artisan Labs demonstrates how precision engineering and scientific innovation are revolutionizing contract manufacturing for the global beauty industry.

The facility's impressive operational capabilities—mixing and measuring with laboratory precision while scaling to commercial production volumes—showcase why 25 international beauty brands have rapidly adopted Artisan Labs as their preferred manufacturing partner for over 100 active projects.

The Art of Precision: Manufacturing Excellence in Action

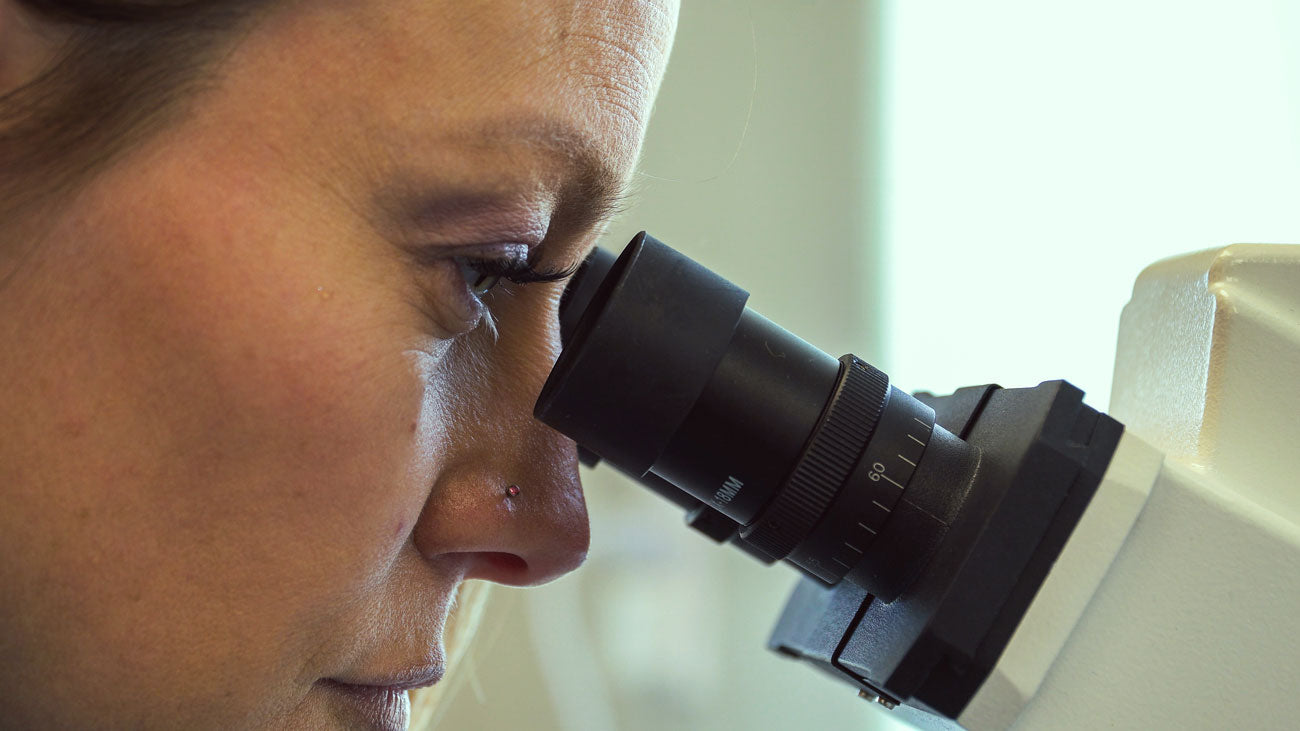

Mara Reed, Research and Development Manager, leads visitors through the sophisticated processes that transform raw ingredients into market-ready cosmetic products. The operation reveals how modern contract manufacturing combines artisanal attention to detail with industrial-scale efficiency.

Revolutionary Mixing and Measuring Protocols

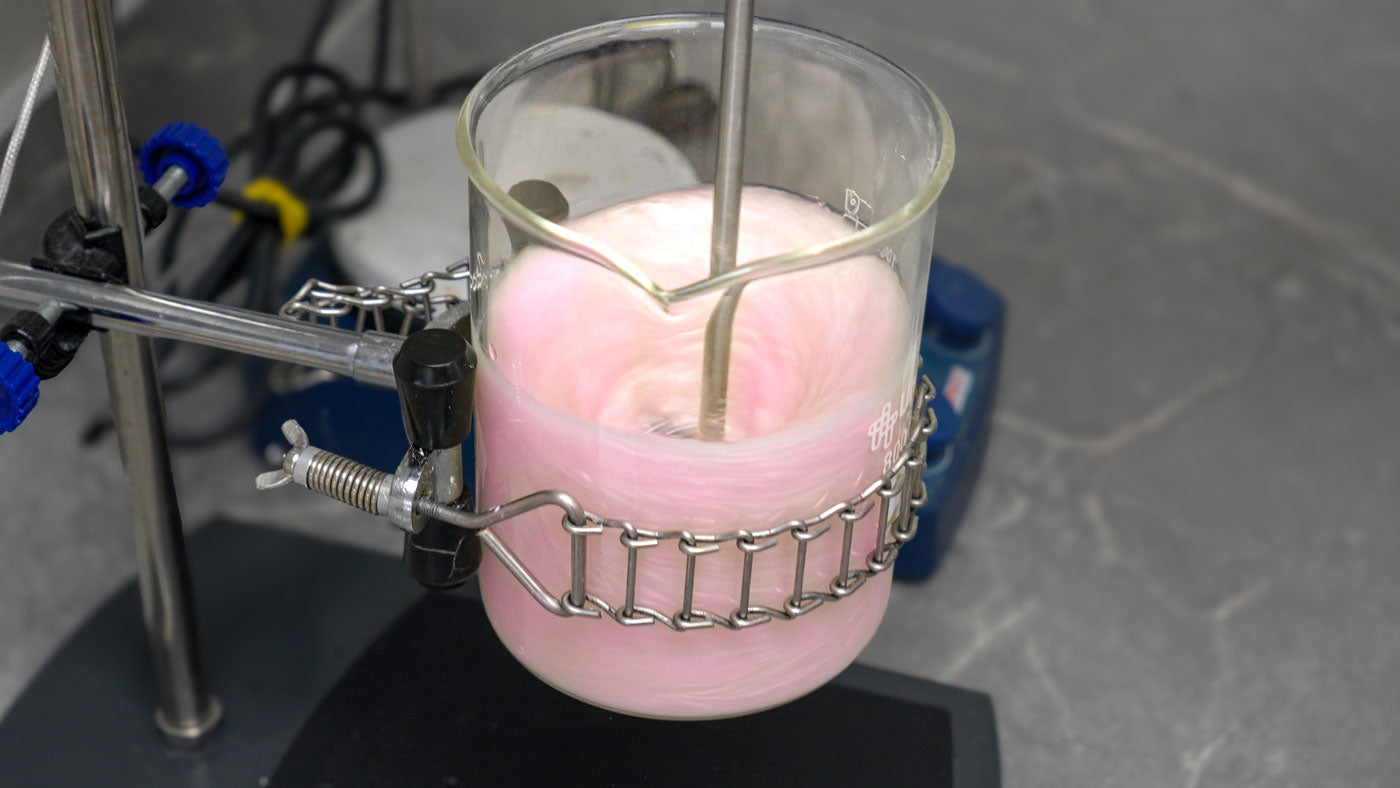

The Artisan Labs manufacturing floor operates like a precision instrument, where every measurement, every mixing cycle, and every quality checkpoint contributes to consistent, superior product outcomes.

Micro-Precision Measuring: Advanced weighing and measuring systems ensure ingredient ratios are maintained within tolerances that exceed industry standards, critical for both product performance and regulatory compliance.

Controlled Mixing Environments: Temperature-controlled mixing processes and specialized equipment create optimal conditions for different formulation types, from lightweight serums to rich moisturizers.

Real-Time Quality Monitoring: Continuous testing throughout the manufacturing process ensures that every batch meets the exacting standards that prestige beauty brands require.

Documentation Excellence: Comprehensive batch records and process documentation provide complete traceability and support regulatory compliance across international markets.

From Concept to Reality: The "Bringing Cosmetics to Life" Process

The phrase "bringing cosmetics to life" captures the transformation that occurs when innovative formulations meet precision manufacturing capabilities at the Artisan Labs facility.

The Complete Manufacturing Journey

Formula Translation: Converting R&D laboratory formulations into scalable manufacturing processes requires sophisticated process engineering and equipment calibration.

Ingredient Integration: Precise sequencing and blending of diverse ingredients—from active compounds to texture modifiers—creates the final product characteristics that consumers experience.

Quality Validation: Multi-stage testing ensures that manufactured products maintain the performance characteristics, safety profiles, and sensory experiences developed during formulation.

Packaging Integration: Coordination with packaging suppliers and fill-finish operations ensures that products maintain quality through the complete production chain.

Operational Excellence: The Numbers Behind the Success

The rapid scaling from startup to 100+ active projects reflects operational capabilities that traditional manufacturers often struggle to achieve, even with decades of experience.

Manufacturing Metrics That Define Excellence

25 International Beauty Brands: Diverse client portfolio requiring flexibility across formulation types, batch sizes, and regulatory requirements.

100+ Active Projects: Simultaneous management of multiple product lines, each with unique specifications and quality standards.

Rapid Turnaround Times: Streamlined processes that accelerate time-to-market for beauty brands in competitive markets.

Zero Compromise Quality: Consistent product quality across all batch sizes, from initial production runs to large-scale commercial manufacturing.

What Makes Artisan Labs Different

Flexible Production Systems: Equipment and processes designed for diverse product types rather than single-category optimization.

Scientific Integration: Seamless connection between R&D development and manufacturing execution, eliminating common translation errors.

Client Collaboration: Manufacturing processes that accommodate brand-specific requirements and quality standards.

Continuous Improvement: Ongoing optimization of processes based on client feedback and industry best practices.

The Technology Behind Manufacturing Innovation

Artisan Labs' manufacturing capabilities represent a significant investment in cutting-edge equipment and process technologies that enable superior outcomes for beauty brand partners.

Advanced Manufacturing Technologies

Precision Mixing Systems: Multi-speed, temperature-controlled mixing equipment that can handle everything from gentle emulsions to high-shear applications.

Automated Dosing Systems: Computer-controlled ingredient addition that ensures consistent formulations and reduces human error.

Environmental Controls: Climate-controlled manufacturing environments that maintain optimal conditions for different product types.

Quality Testing Equipment: In-line testing capabilities that provide real-time feedback on product characteristics and consistency.

Process Innovation Advantages

Scalable Flexibility: Manufacturing systems that adapt to different batch sizes without compromising quality or efficiency.

Cross-Contamination Prevention: Sophisticated cleaning and changeover protocols that enable multi-product manufacturing without quality risks.

Waste Minimization: Efficient processes that reduce material waste and optimize resource utilization.

Regulatory Compliance: Built-in documentation and quality systems that support FDA compliance and international regulatory requirements.

The Human Element: Expertise That Drives Excellence

While technology provides the foundation, the Artisan Labs team's expertise transforms advanced equipment into world-class manufacturing outcomes.

Manufacturing Team Excellence

Experienced Leadership: Management team with decades of combined experience in cosmetic manufacturing and quality systems.

Skilled Technicians: Production staff trained in both technical processes and quality standards specific to prestige beauty products.

Continuous Training: Ongoing education programs that keep the team current with industry developments and best practices.

Safety Culture: Comprehensive safety protocols that protect both personnel and product quality.

The Precision Mindset

Attention to Detail: Every step of the manufacturing process receives the same level of care and precision, regardless of batch size or product complexity.

Quality First: Decision-making processes that prioritize quality outcomes over production efficiency when conflicts arise.

Client Focus: Manufacturing approaches tailored to each brand's specific requirements and quality expectations.

Innovation Adoption: Willingness to implement new technologies and processes that improve outcomes for clients.

Manufacturing Scalability: Growing with Client Success

Artisan Labs' rapid expansion from startup to managing over 100 active projects demonstrates manufacturing systems designed for scalable growth rather than fixed capacity constraints.

Scalability Strategies

Modular Equipment: Manufacturing systems that can be expanded incrementally as client demands increase.

Flexible Scheduling: Production planning that optimizes equipment utilization while meeting diverse client timeline requirements.

Inventory Management: Sophisticated ingredient sourcing and inventory systems that support increasing production volumes.

Quality Consistency: Standardized processes that maintain quality standards regardless of production scale.

Future Manufacturing Capabilities

Expansion Planning: Strategic investments in additional equipment and facility space to support continued client growth.

Technology Upgrading: Ongoing evaluation and implementation of new manufacturing technologies that enhance capabilities.

Process Optimization: Continuous improvement initiatives that increase efficiency while maintaining quality standards.

Market Adaptation: Manufacturing flexibility that enables response to changing industry trends and client requirements.

Quality Systems: The Foundation of Manufacturing Excellence

Every mixing cycle, every measurement, every quality check at Artisan Labs operates within comprehensive quality management systems that ensure consistent outcomes for all clients.

Comprehensive Quality Management

Statistical Process Control: Data-driven monitoring of manufacturing processes that identifies and addresses variations before they impact product quality.

Batch Documentation: Complete records for every production run that support regulatory compliance and enable continuous improvement.

Supplier Qualification: Rigorous evaluation and ongoing monitoring of ingredient suppliers to ensure consistent input quality.

Equipment Calibration: Regular calibration and maintenance programs that ensure manufacturing equipment operates within specifications.

Regulatory Compliance Excellence

FDA Standards: Manufacturing processes designed to meet and exceed FDA requirements for cosmetic production.

International Standards: Quality systems that support export to diverse international markets with varying regulatory requirements.

Documentation Systems: Comprehensive record-keeping that supports regulatory inspections and client audits.

Continuous Monitoring: Ongoing evaluation of regulatory developments to ensure continued compliance.

The Economic Impact of Manufacturing Innovation

Artisan Labs' manufacturing excellence extends beyond individual client relationships to create broader economic benefits for Idaho's manufacturing sector and rural economic development.

Regional Manufacturing Leadership

High-Skill Job Creation: Manufacturing positions requiring technical expertise and precision skills that provide career advancement opportunities.

Supplier Network Development: Relationships with ingredient and packaging suppliers that benefit the broader regional economy.

Manufacturing Reputation: Establishing Idaho as a location for sophisticated, high-quality manufacturing operations.

Innovation Culture: Demonstrating that rural locations can support world-class manufacturing capabilities.

Industry Influence

Setting New Standards: Manufacturing excellence that influences industry expectations and competitive benchmarks.

Best Practice Development: Process innovations that contribute to broader industry advancement.

Talent Development: Training and development programs that build specialized capabilities in the regional workforce.

Supply Chain Optimization: Efficient operations that demonstrate the advantages of strategic location decisions.

Client Success Through Manufacturing Partnership

The 25 international beauty brands working with Artisan Labs represent diverse market segments and product categories, each benefiting from manufacturing capabilities tailored to their specific requirements.

Manufacturing Advantages for Beauty Brands

Reduced Time-to-Market: Streamlined manufacturing processes that accelerate product launch timelines.

Quality Assurance: Consistent manufacturing outcomes that protect brand reputation and consumer satisfaction.

Cost Optimization: Efficient operations that provide competitive manufacturing costs without compromising quality.

Regulatory Support: Manufacturing compliance that simplifies market entry and ongoing regulatory management.

Scalability Planning: Manufacturing capabilities that grow with brand success and market expansion.

Long-Term Partnership Benefits

Continuous Improvement: Ongoing optimization of manufacturing processes based on client feedback and market requirements.

Innovation Support: Manufacturing flexibility that enables brands to introduce new product concepts and innovations.

Market Expansion: Manufacturing capabilities that support entry into new geographic markets and consumer segments.

Strategic Planning: Manufacturing partnership that contributes to long-term brand strategy and growth planning.

Looking Forward: The Future of Manufacturing Excellence

Artisan Labs' manufacturing success provides insights into how contract manufacturing is evolving and what capabilities will define industry leaders in the coming years.

Manufacturing Trends and Innovations

Sustainability Integration: Environmental considerations becoming central to manufacturing process design and optimization.

Technology Advancement: Automation and digital monitoring systems that enhance both efficiency and quality outcomes.

Customization Capabilities: Manufacturing flexibility that supports increasing demand for personalized and niche products.

Supply Chain Resilience: Diversified sourcing and flexible manufacturing that adapts to changing market conditions.

Strategic Manufacturing Vision

Continuous Innovation: Ongoing investment in new technologies and processes that maintain competitive advantages.

Quality Leadership: Commitment to quality standards that exceed industry norms and client expectations.

Sustainable Growth: Expansion strategies that maintain quality and service levels while increasing capacity and capabilities.

Industry Partnership: Collaboration with clients, suppliers, and industry organizations to advance manufacturing excellence.

Conclusion: Where Manufacturing Meets Innovation

The precision mixing and measuring operations at Artisan Labs represent more than just efficient manufacturing—they demonstrate how next-generation contract manufacturers are redefining industry standards through scientific rigor, technological innovation, and unwavering commitment to quality.

From the careful measurement of ingredients to the final quality verification, every step of the manufacturing process reflects the precision and expertise that has enabled Artisan Labs to rapidly become the preferred partner for 25 international beauty brands managing over 100 active projects.

The story being written on the Artisan Labs manufacturing floor showcases the potential for American manufacturing to compete globally through innovation, quality, and operational excellence. As the company continues to expand its capabilities and client portfolio, it's not just participating in the evolution of contract manufacturing—it's helping to define what manufacturing excellence looks like in the modern beauty industry.

For beauty brands seeking manufacturing partners who understand that precision and quality are non-negotiable, the Artisan Labs operation demonstrates what's possible when scientific expertise meets manufacturing innovation in a facility designed for excellence.

This is how cosmetics come to life in the new era of contract manufacturing—through precision, innovation, and an unwavering commitment to bringing beauty brands' visions to reality with uncompromising quality.

Ready to experience manufacturing excellence that brings your cosmetic vision to life? Contact Artisan Labs to schedule a facility tour and discover how our precision manufacturing capabilities can accelerate your brand's success.

About Manufacturing Excellence: The precision operations at Artisan Labs represent a new standard in contract manufacturing, where scientific rigor meets commercial scalability to deliver exceptional outcomes for international beauty brands. For more information about our manufacturing capabilities, visit our facility at 290 Highway 30 in Hansen, Idaho.