Building Tomorrow's Workforce: How Contract Manufacturers Drive STEM Education Innovation

Share

The future of American manufacturing depends on cultivating the next generation of innovators, engineers, and problem-solvers. At Artisan Labs, we understand that contract manufacturing success isn't just about delivering exceptional products today—it's about investing in the workforce that will drive innovation tomorrow.

Recently, our team had the privilege of participating in the Idaho STEM Ecosystem's inaugural convening at the College of Southern Idaho, where industry leaders came together with educators to address one of the most critical challenges facing manufacturing: bridging the gap between STEM education and real-world industry applications.

The Critical Connection: STEM Education and Contract Manufacturing Excellence

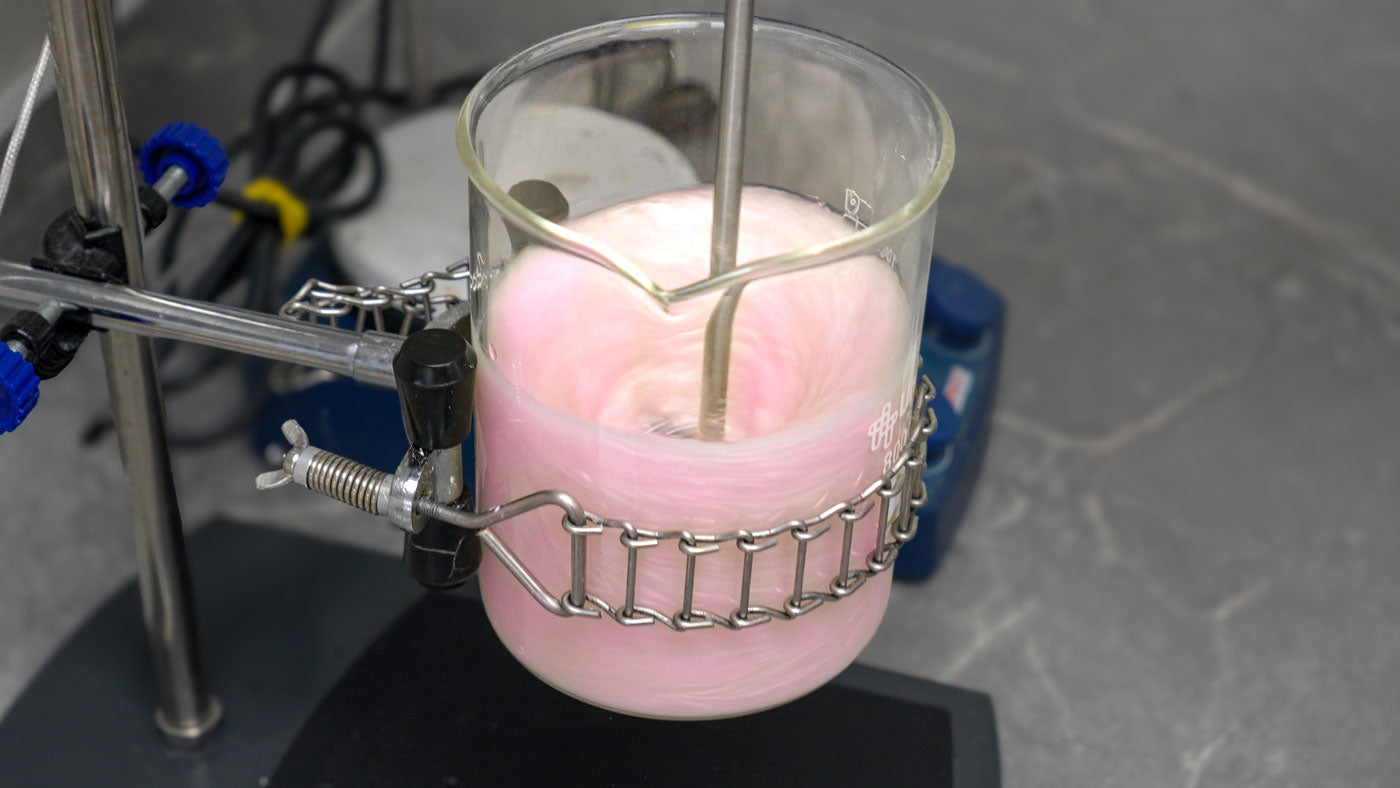

As a leading contract manufacturer specializing in cosmetic formulation and product development, Artisan Labs has witnessed firsthand how strong STEM foundations translate into manufacturing innovation. The skills students develop through science, technology, engineering, and mathematics education directly correlate with the competencies needed in modern contract manufacturing facilities.

Why STEM Education Matters for Manufacturing Partners

Advanced Formula Development: Today's cosmetic and personal care products require sophisticated understanding of chemistry, materials science, and process engineering. Contract manufacturers need team members who can navigate complex formulation challenges, understand molecular interactions, and optimize manufacturing processes for scalability and efficiency.

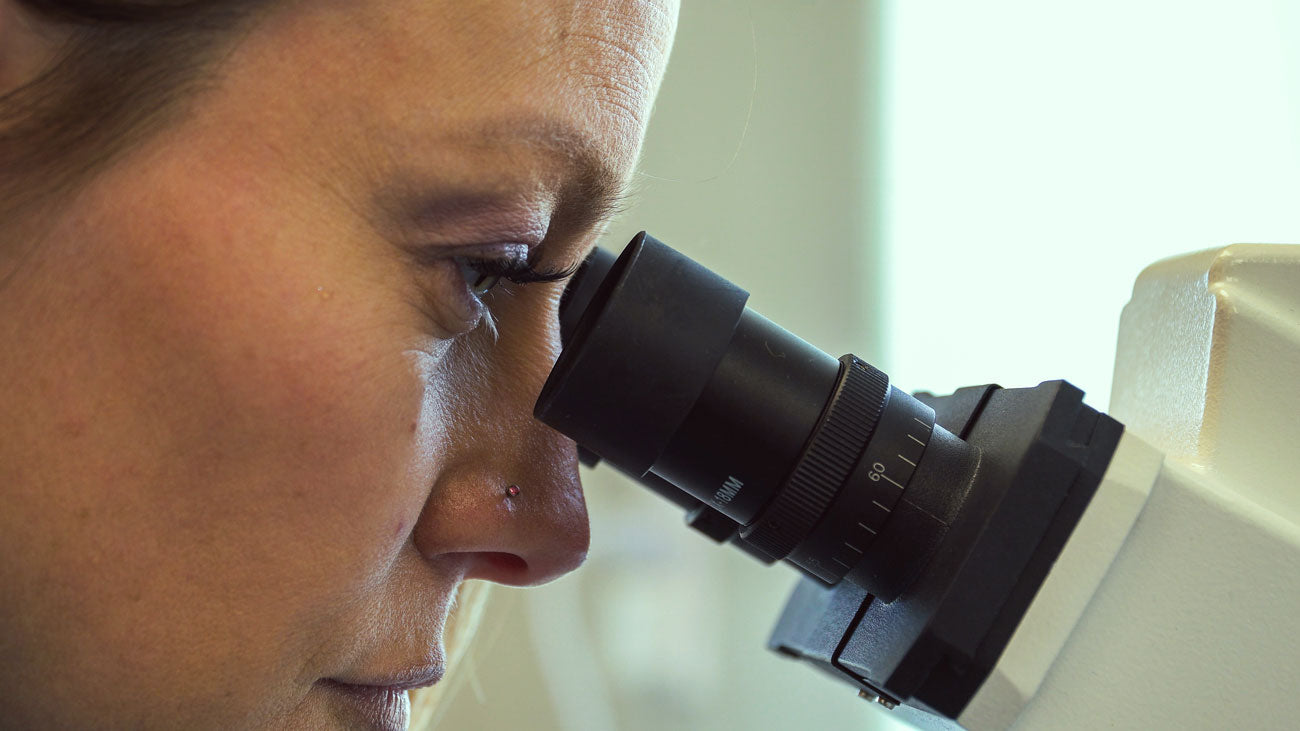

Quality Control and Testing: Modern contract manufacturing operations rely heavily on analytical chemistry, statistical process control, and data analysis. STEM-educated professionals bring the critical thinking skills necessary to implement robust quality systems, interpret complex test results, and ensure regulatory compliance across diverse product lines.

Innovation and Problem-Solving: The most successful contract manufacturers differentiate themselves through innovation. Whether developing new delivery systems, optimizing manufacturing processes, or solving unique formulation challenges, STEM education provides the foundation for creative problem-solving that drives industry advancement.

Artisan Labs' Commitment to STEM Education Partnership

During the Idaho STEM Ecosystem conference, our team joined colleagues from Glanbia and Idaho Power to discuss how Idaho contract manufacturers are actively incorporating educational partnerships into their business strategies. This collaborative approach benefits both the educational community and the manufacturing sector.

Bridging the Education-Industry Gap

As one panelist noted during the conference, "We need to stop looking for the things that divide us and look for the things that unite us." This philosophy guides our approach to STEM education partnerships:

Real-World Application: We provide students with opportunities to see how classroom concepts apply in professional manufacturing environments. From basic chemistry principles used in formulation development to advanced engineering concepts in process optimization, students gain practical context for their studies.

Career Pathway Visibility: Many students don't realize the diverse career opportunities available in contract manufacturing. Through educational partnerships, we showcase roles in quality assurance, formulation science, regulatory affairs, operations management, and product development.

Hands-On Learning Opportunities: The best STEM education combines theoretical knowledge with practical application. We support programs that give students access to real manufacturing challenges, laboratory experiences, and industry-standard equipment.

The Innovation Pipeline: From Student Projects to Manufacturing Solutions

The Idaho STEM Ecosystem conference highlighted remarkable student innovation, including projects like the "Hope Notes" dispenser developed by local students in response to community mental health challenges. This type of solution-oriented thinking exemplifies the innovation mindset that drives successful contract manufacturing.

Student Innovation Mirrors Manufacturing Innovation

Problem Identification: Just as students identified a community need and developed a solution, successful contract manufacturers excel at identifying market gaps and developing products to fill them.

Iterative Design Process: The engineering design process taught in STEM programs—define, design, test, refine—mirrors the product development lifecycle in contract manufacturing.

Collaborative Problem-Solving: Manufacturing success requires cross-functional collaboration. STEM education emphasizes teamwork and communication skills essential for coordinating complex manufacturing projects.

Regional Manufacturing Strength Through Educational Investment

Idaho's growing reputation as a manufacturing hub correlates directly with the strength of its educational institutions and STEM programs. Regional contract manufacturers benefit from this educational foundation in multiple ways:

Developing Local Talent

Strong STEM programs create a pipeline of qualified candidates for technical roles in contract manufacturing. This reduces recruitment costs and builds long-term community relationships that benefit both manufacturers and educational institutions.

Fostering Innovation Culture

Communities with robust STEM education tend to develop cultures of innovation that attract manufacturing investment. This creates a positive feedback loop where educational strength attracts industry, which in turn supports further educational development.

Addressing Skills Gaps

The manufacturing sector faces significant skills gaps in technical areas. Proactive investment in STEM education helps address these gaps before they become critical limitations to growth.

Contract Manufacturing's Role in STEM Education Success

Private label manufacturers and contract manufacturing companies play crucial roles in supporting STEM education beyond simple financial contributions:

Providing Real-World Context

Manufacturing partners can offer authentic problem-solving scenarios for student projects. Whether optimizing production efficiency, developing sustainable packaging solutions, or creating new product formulations, real industry challenges provide meaningful learning opportunities.

Mentorship and Expertise

Industry professionals bring practical experience that complements academic instruction. Our team members regularly engage with local educational programs, sharing insights about career paths, industry trends, and the practical application of STEM concepts.

Equipment and Facility Access

Modern manufacturing facilities contain sophisticated equipment and testing capabilities that can enhance educational programs. Strategic partnerships allow students to access industry-standard tools and environments.

The Future of Manufacturing Education Partnerships

As we look toward the future, the relationship between STEM education and contract manufacturing will continue to evolve:

Emerging Technology Integration

Smart manufacturing, automation, and data analytics are reshaping the industry. Educational programs must evolve to prepare students for these technology-driven environments.

Sustainability Focus

Environmental consciousness drives innovation in contract manufacturing. STEM programs increasingly emphasize sustainable design principles that align with industry needs for eco-friendly products and processes.

Entrepreneurship Development

Many STEM graduates will become entrepreneurs, potentially becoming the next generation of manufacturing innovators. Educational programs that combine technical skills with business acumen prepare students for leadership roles in the industry.

Building Generational Impact Through Partnership

The Idaho STEM Ecosystem's goal of creating "generational impact" resonates strongly with our mission at Artisan Labs. Sustainable contract manufacturing requires long-term thinking about workforce development, community investment, and educational partnerships.

Creating Transformative Learning Experiences

Effective STEM education goes beyond textbook learning to create transformative experiences that inspire lifelong learning and innovation. Manufacturing partnerships can provide these experiences through:

- Laboratory Collaborations: Sharing analytical capabilities and expertise

- Project Sponsorship: Supporting student research projects with real-world applications

- Career Exploration: Hosting facility tours, internships, and job shadowing opportunities

- Professional Development: Supporting educator professional development in manufacturing technologies

Measuring Impact and Success

Successful educational partnerships require clear metrics and ongoing evaluation:

Student Outcomes: Tracking graduation rates, college enrollment, and career placement in STEM fields Program Enhancement: Evaluating how industry partnerships improve educational program quality and relevance Community Benefits: Assessing broader community impact through improved economic development and workforce readiness

The Competitive Advantage of Educational Investment

For contract manufacturers seeking sustainable growth, investment in STEM education provides multiple competitive advantages:

Talent Pipeline Development

Companies that invest in education build relationships with future employees, creating talent pipelines that support long-term growth strategies.

Innovation Enhancement

Educational partnerships expose manufacturing teams to fresh perspectives and emerging technologies, driving innovation and competitive differentiation.

Community Relations

Strong educational partnerships enhance community relationships, supporting business development and regulatory engagement.

Brand Differentiation

Companies known for educational investment attract customers and partners who value social responsibility and community engagement.

Looking Forward: The Next Generation of Manufacturing Innovation

As we continue our participation in Idaho's STEM education ecosystem, Artisan Labs remains committed to fostering the next generation of manufacturing innovators. The students participating in programs like the Elementary STEM program at the Twin Falls Public Library and the Idaho Exhibition of Ideas STEM Showcase represent the future of our industry.

Call to Action for the Manufacturing Community

The success of STEM education requires broad industry engagement. We encourage fellow contract manufacturing companies to:

- Engage with Local Schools: Establish relationships with area educational institutions

- Share Expertise: Volunteer time and knowledge to support STEM programs

- Provide Real-World Context: Offer authentic problems and projects for student learning

- Support Educators: Invest in teacher professional development and classroom resources

- Create Pathways: Develop internship and apprenticeship programs that bridge education and employment

Conclusion: Partnering for Manufacturing Excellence

The future of contract manufacturing depends on the strength of our educational partnerships today. By investing in STEM education, supporting innovative programs, and actively engaging with educational communities, manufacturers can build the workforce needed for continued innovation and growth.

At Artisan Labs, our participation in the Idaho STEM Ecosystem represents our commitment to this vision. We believe that by working together—educators, students, and industry professionals—we can create the foundation for sustained manufacturing excellence and community prosperity.

The gap between education and industry doesn't have to be a barrier. With intentional partnership and shared commitment to student success, it becomes a bridge to innovation, opportunity, and shared prosperity.

Ready to partner with a contract manufacturer that values innovation, quality, and community investment? Contact Artisan Labs today to discuss how our STEM-educated team can bring scientific excellence to your next product development project.